Filling Machine Volumetric

Prominent & Leading Manufacturer from Vapi, we offer two head semi-automatic filling machine, automatic twin head liquid filling machine and automatic four head filling machine.

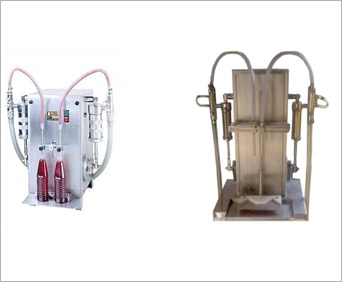

Two Head Semi-automatic Filling Machine

Product Details:

|

Machine Type |

Semi-Automatic / Automatic |

|

Brand |

Sumitech |

|

Output / Hour |

1400-8000 |

|

Phase |

3 |

|

Length |

1800-1850 |

|

Width |

840-1050 |

|

Height |

1300-1400 |

|

Head |

Two |

|

Driven Type |

Electric |

|

Fill Size |

50 ml to 1000 ml |

We are leading manufacturer and exporter of Two Head Semi Automatic Filling machine and our product is made up of good quality.

Our offered machine is used for the filling of liquid products in various industries. Our company uses high-quality components & the latest techniques to design this machine, as per the particular need of our clients. We provide this machine in different models and other technical specifications in line with clients’ particular needs.

Features:

- Proper functioning

- Application specific design

- High operational fluency

- Low maintenance cost

Other Details:

- 0.5 to 1% Filling accuracy on single dose

- Rigid vibration free construction for trouble free performance

- S.S. elegantly matt finished body

- Elegant and easy control panel for total control on operation

- Minimum changeover time, from one size to another container or fill size

- Automatic washing of conveyor belt (Optional)

- Reciprocating filling nozzle with self-cantering device to avoid foaming

- The unit is made compact & versatile-as per GMP norms

- No container no filling system-to avoid spillage

- Synchronised A.C. drives for conveyor & main drive

- Pneumatic control bottle stopper/Mechanical bottle control

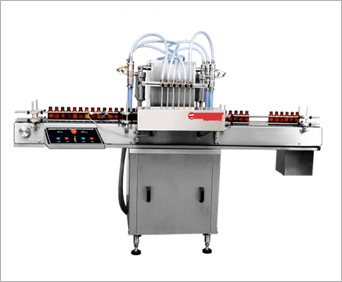

Automatic Four / Six / Eight Head Filling Machine

Product Details:

|

Machine Type |

Semi-Automatic / Automatic |

|

Brand |

Sumitech |

|

Output / Hour |

1400-8000 |

|

Phase |

3 |

|

Length |

1800-1850 |

|

Width |

840-1050 |

|

Height |

1300-1400 |

|

Head |

Four / Six / Eight |

|

Driven Type |

Electric |

|

Fill Size |

50 ml to 1000 ml |

Other Details :

- 0.5 to 1% Filling accuracy on single dose

- Rigid vibration free construction for trouble free performance

- S.S. elegantly matt finished body

- Elegant and easy control panel for total control on operation

- Minimum change over time, from one size to another container or fill size

- Automatic washing of conveyor belt (Optional)

- Reciprocating filling nozzle with self-cantering device to avoid foaming

- The unit is made compact & versatile-as per GMP norms

- No container no filling system-to avoid spillage

- Synchronised A.C. drives for conveyor & main drive

- Pneumatic control bottle stopper/Mechanical bottle control

Instructions :

|

Model No. |

SE – VFM – 2H |

SE – VFM – 4H |

SE-VFM – 6H |

SE- VFM – 8H |

|

Output / Hour |

1400 to 3200 |

1400 to 3200 |

3200 to 6000 |

6000 to 8000 |

|

Electric Motor |

Main Machine |

2 HP/440 Volts/3 Phase/50 (Four Wire) |

3 HP/440 Volts/3 Phase/50 (Four Wire) |

3HP/440 Volts/3 Phase/50 (Four Wire) |

|

0.5 HP/440 Volts/3 Phase/50 (Four Wire) |

0.5 HP/440 Volts/3 Phase/50 (Four Wire) |

0.5 HP/440 Volts/3 Phase/50 (Four Wire) |

0.5 HP/440 Volts/3 Phase/50 (Four Wire) |

|

|

Container Size |

Ø 30 mm to Ø 100 mm, Maximum height 280 mm |

Ø 30 mm to Ø 100 mm, Maximum height 280 mm |

Ø 30 mm to Ø 100 mm, Maximum height 280 mm |

Ø 30 mm to Ø 100 mm, Maximum height 280 mm |

|

Fill Size |

10 ml. to 1000 ml (with the help of required change part) |

10 ml. to 1000 ml (with the help of required change part) |

10 ml. to 1000 ml (with the help of required change part) |

10 ml. to 1000 ml (with the help of required change part) |

Piston Filling Machine

Product Details:

|

Brand |

Sumitech |

|

Control type |

PLC |

|

Material |

Stainless Steel |

|

Power |

120v/110v |

We are leading manufacturer and exporter of Piston Filling Machine and our product is made up of good quality.

Piston Filling Machine offered comes backed by advanced technology support and perfectly meets the demands of automatic piston filling requirements. Further, the piston support used as well as precise mechanical and electrical component integration also assure of the reliable and accurate performance of the systems.

Features :

- Advanced PLC control support

- Compact structure finish

- Allowing stable and reliable operations

- High filling accuracy and quick adaptability to different filling conditions

- Allows for easy maintenance.